Pasteurise Mushroom Substrate at Home

Pasteurising mushroom substrate at home is one of the most important — and most misunderstood — steps in successful mushroom cultivation. Whether you’re growing gourmet mushrooms or working with bulk substrates for more advanced grows, proper pasteurisation determines colonisation speed, contamination risk, and shelf life.

In this guide, we’ll explain:

What substrate pasteurisation actually does

Three common home pasteurisation methods used by growers

The hidden contamination risk most growers don’t realise

Why a sealed, all-in-one boil-in-the-bag method solves these problems

This article is written for home growers, not labs — practical, realistic, and contamination-aware.

What Is Substrate Pasteurisation?

Pasteurisation is the process of reducing harmful competitor organisms (moulds, bacteria, yeasts) while preserving beneficial thermophilic microbes that help protect your substrate after cooling.

Unlike sterilisation (which kills everything), pasteurisation:

Targets temperatures of 60–80°C

Reduces pathogen load without creating a sterile vacuum

Produces a substrate that mycelium can outcompete naturally

This balance is why pasteurisation is preferred for bulk substrates recipes like coco coir, CVG, straw, and supplemented mixes.

The Real Problem Most Home Growers Face (But Rarely Identify)

Most guides focus on how to heat substrate — but the real risk happens after heating.

Once substrate cools, any exposure to open air allows fresh contaminants to settle onto a now nutrient-rich, moist surface. Even clean kitchens contain:

Trichoderma spores

Bacillus bacteria

Airborne moulds

Skin and dust contaminants

If substrate is mixed, transferred, or handled in open air after cooling, contamination risk increases and shelf life drops dramatically.

This is where traditional methods fall short. Contamination in Mycology

3 Common Home Pasteurisation Methods (And Their Limitations)

1. Hot Water Bucket Pasteurisation (The Most Common Method)

How it works

Dry substrate is placed in a bucket or tub

Boiling water is poured over it

Lid is closed and allowed to cool

Substrate is later mixed and drained by hand

Pros

Cheap and accessible

Works reasonably well for coco coir and CVG

No special equipment required

Cons

Substrate must be opened and mixed after cooling

Hands, air, and tools reintroduce contaminants

Field capacity adjustment is inconsistent

Shorter shelf life

2. Oven Pasteurisation (Tray or Foil Method)

How it works

Hydrated substrate is placed in trays or foil pans

Heated in an oven at ~70–80°C for 1–2 hours

Removed and allowed to cool before use

Pros

Temperature can be controlled

More uniform heating

Suitable for small batches

Cons

Risk of drying substrate unevenly

Still requires open-air handling after cooling

Energy inefficient

Not scalable

3. Stove-Top Pot or Pillowcase Method (Straw & Fibrous Substrates)

How it works

Substrate placed in a fabric bag or pot

Submerged in hot water for a fixed time

Removed, drained, cooled, and mixed

Pros

Effective for straw and wood-based substrates

Traditional and proven

Cons

Draining exposes substrate to airborne spores

Fabric bags can harbour contaminants

Messy and inconsistent hydration

The Hidden Weak Point: Post-Pasteurisation Exposure

All traditional home methods share one flaw:

The substrate is pasteurised… then opened, mixed, adjusted, and handled in unfiltered air.

This leads to:

Reduced shelf life

Higher contamination rates

Inconsistent results

“It worked last time but not this time” grows

Even experienced growers unknowingly reintroduce contaminants during mixing.

The All-in-One Boil-in-the-Bag Home Pasteurisation Method (Sealed From Start to Finish) 2025.

How the Method Works

All dry ingredients are added to a single mushroom grow bag

Coco coir

Vermiculite

Supplements (e.g. soya hull pellets)

The exact volume of boiling water is added directly to the bag

The bag is sealed immediately

Using a heat sealer or sealer stick

The sealed bag is insulated

Wrapped or placed in a thermal environment

Heat is retained for effective pasteurisation

Substrate cools completely while sealed

Substrate is mixed inside the closed bag

No open air

No handling

No recontamination

Why This Method Is Fundamentally Better

Closed-System Pasteurisation

Closed-System Pasteurisation

The substrate is never exposed to unpasteurised air after heating.

Mixing Happens Inside the Pasteurised Environment

Mixing Happens Inside the Pasteurised Environment

Traditional methods pasteurise → cool → contaminate during mixing.

This method pasteurises → cools → remains clean throughout.

Longer Shelf Life

Longer Shelf Life

With no post-cooling exposure:

Substrate stays viable for longer

Less microbial rebound

Better storage flexibility

More Consistent Field Capacity

More Consistent Field Capacity

Water is measured precisely and absorbed evenly during insulation.

Lower Skill Barrier for Beginners

Lower Skill Barrier for Beginners

Removes:

Guesswork

Draining errors

Hygiene mistakes

| Method | Post-Cooling Exposure | Mixing Environment | Shelf Life | Contam Risk |

|---|---|---|---|---|

| Bucket Method | High | Open air | Short | Medium–High |

| Oven Method | Medium | Open air | Short–Medium | Medium |

| Stove/Pot Method | High | Open air | Short | High |

| Boil-in-Bag Method | None | Sealed bag | Long | Lowest |

Why This Matters for Modern Home Cultivation

As substrates become more nutrient-rich (supplements, pellets, additives), contamination tolerance drops. What worked ten years ago doesn’t scale cleanly today.

This sealed, all-in-one pasteurisation method aligns with:

Modern grow bag systems

Higher supplementation ratios

Longer storage expectations

Cleaner, more repeatable home workflows

It doesn’t replace sterilisation where required — but for bulk substrate pasteurisation, it closes the biggest contamination loophole home growers face.

Final Thoughts

Pasteurisation isn’t just about heat — it’s about what happens after the heat is gone.

Traditional home methods stop protecting the substrate at the exact moment it becomes most vulnerable. Once cooling begins, open-air handling and mixing allow fresh contaminants to settle onto a nutrient-rich surface, reducing shelf life and increasing the risk of failure.

A sealed, boil-in-the-bag approach keeps the substrate protected from start to finish. By pasteurising, hydrating, cooling, and mixing entirely within a closed environment, this method delivers cleaner substrate, longer shelf life, and more consistent results — especially for home growers without laboratory conditions.

This isn’t just a convenience upgrade — it’s a fundamental process improvement.

This substrate is specifically formulated for monotub mushroom growing, where consistency and contamination resistance matter most.

Ready-to-Use Pasteurised Substrate Options

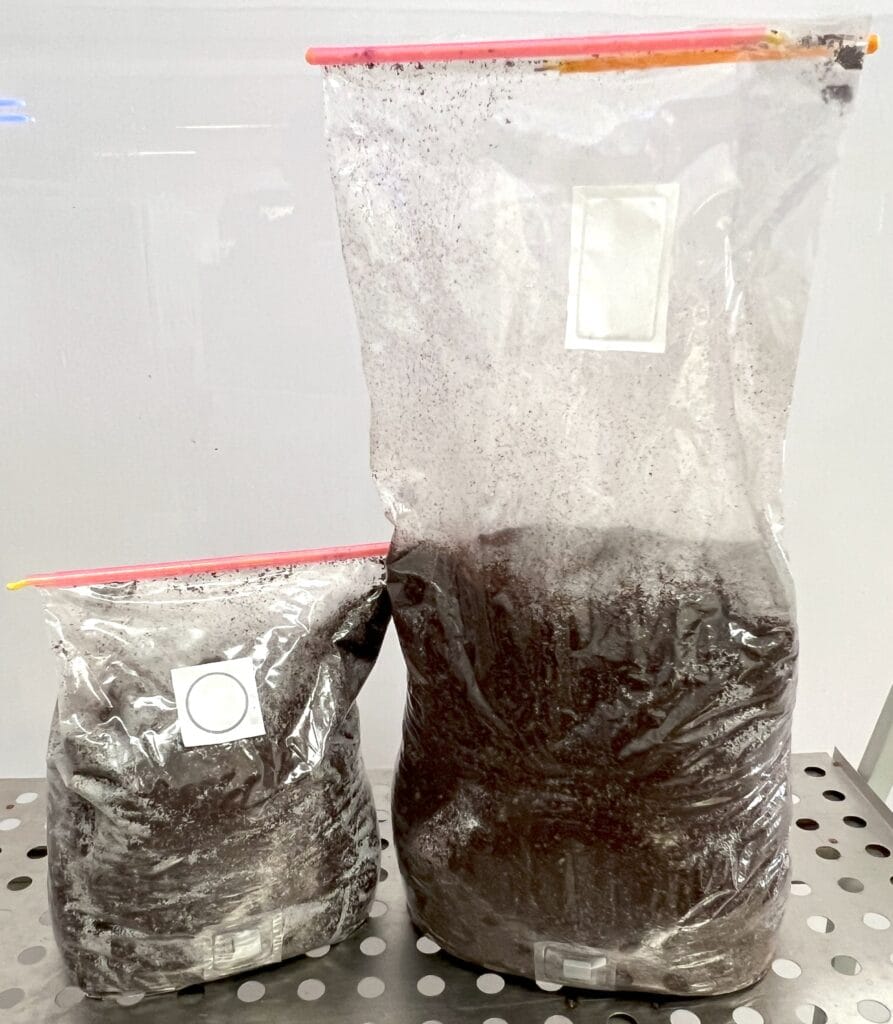

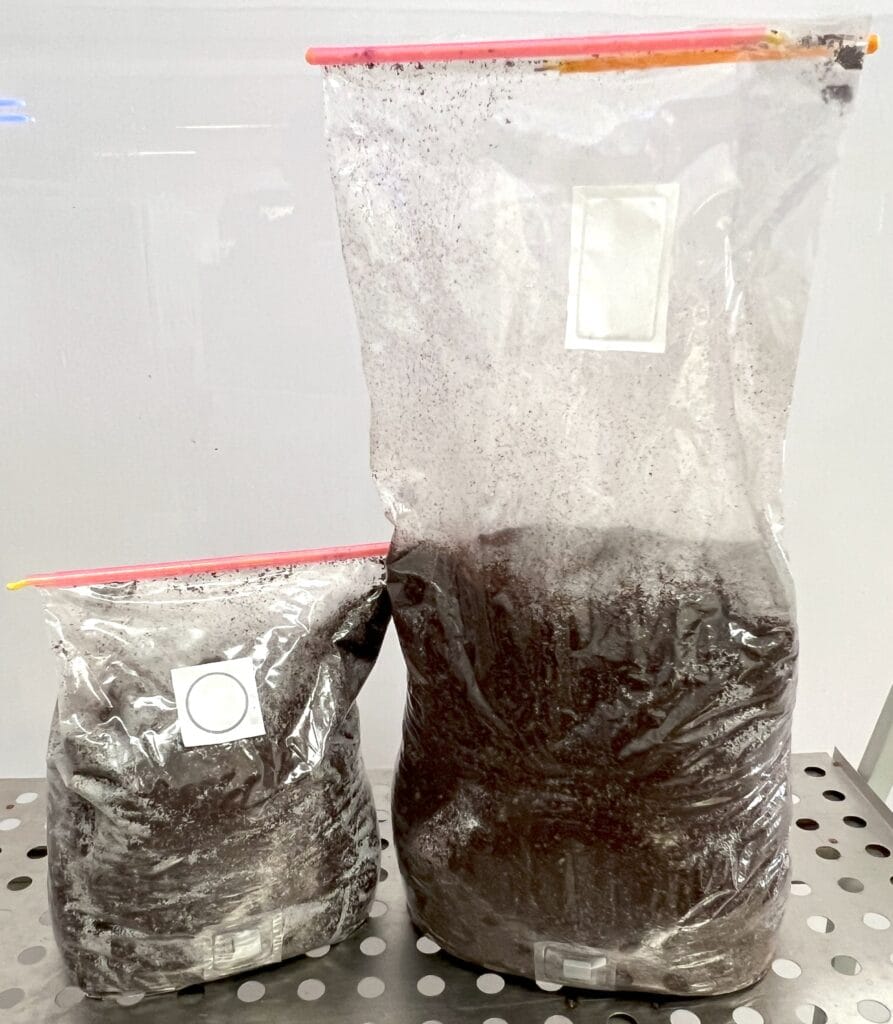

For growers who want the benefits of sealed pasteurisation without the preparation step, we offer ready-made, pasteurised bulk substrate bags prepared using this closed-system method:

3.5kg Pasteurised Bulk Substrate Bag – ideal for small monotub grows, trays, and test runs £21.99

7kg Pasteurised Bulk Substrate Bag – perfect for Larger monotubs fruiting projects £29.99

Both options arrive fully hydrated, sealed, and ready for mixing with Spawn, helping you focus on colonisation and fruiting — not preparation.

How much Grain to bulk substrate do I use?

For Monotubs – 1.5KG colonise rye grain and 3.5KG of pasteurised bulk substrate is enough for the 45L and 80L monotubs. This amount will give a substrate depth of 3-3.5inches and will fully colonise in 7-14days. Monotub mushroom growing Guide.

For Bag Tek – Add 1kg of colonised rye grain to 2kg of Bulk substrate into a bag that is 5 times bigger than the substrate depth.

How long will pasteurised substrate last?

Pasteurised mushroom substrate products are best used as soon as possible or within 10 days for best results.

Closed-System Pasteurisation

Closed-System Pasteurisation Mixing Happens Inside the Pasteurised Environment

Mixing Happens Inside the Pasteurised Environment Longer Shelf Life

Longer Shelf Life More Consistent Field Capacity

More Consistent Field Capacity Lower Skill Barrier for Beginners

Lower Skill Barrier for Beginners